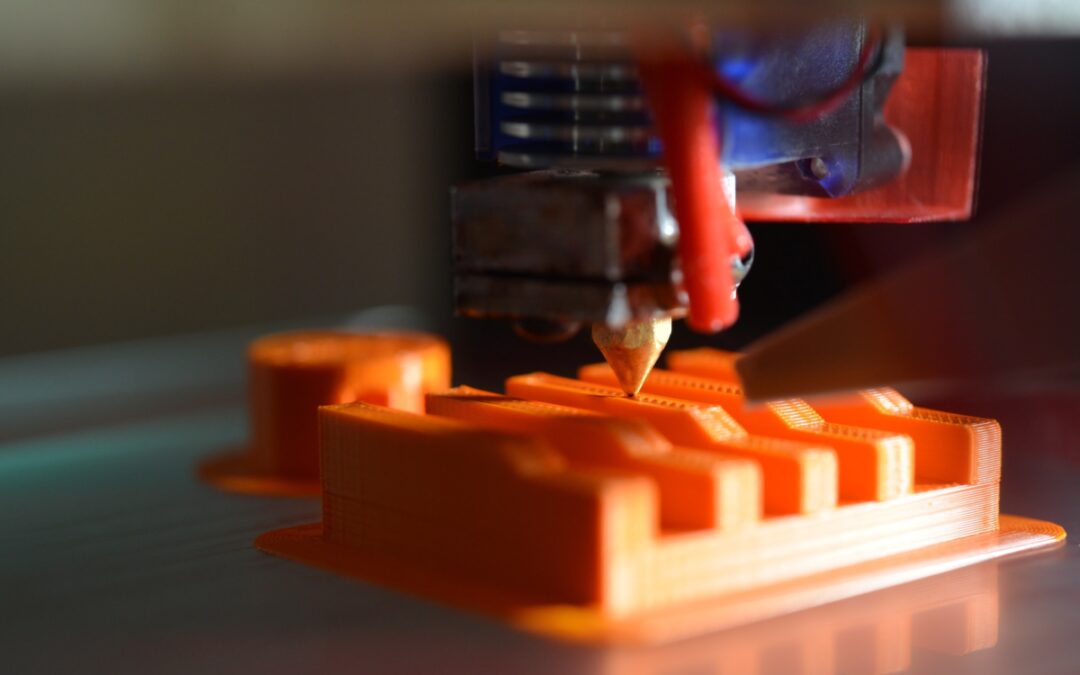

While 3D printing is becoming more popular in today’s world, there are many advantages to using it as well as some disadvantages. Let’s go over the pros and cons when it comes to 3D printing. 3D printing is an innovative manufacturing process that involves creating three-dimensional objects by layering materials based on a digital model. Unlike traditional manufacturing techniques that involve subtracting material through cutting or molding, 3D printing adds material layer by layer, resulting in minimal waste and increased design flexibility.

Pros

One of the most amazing advantages of is how fast parts can be manufactured. Parts can actually be manufactured in just hours. Each stage can then be completed at a much faster rate.

One of the most common materials of 3D printing is plastic. This makes the part much more lightweight which is an advantage. This comes in handy with aerospace as well as the automotive industries.

Since 3D printing takes up little time to manufacture, it also saves on cost. You don’t have to worry about using different machines. Another bonus is it can actually be left for a period of time when printing so you do not have to worry about someone manning the machine the entire time.

Cons

One of the disadvantages is that the printers have very small chambers which hinders the size of the part that will be printed. If you would like to use anything larger, you will have to print that separately.

Another issue is the reduction in people when it comes to labor. Most of the printing is actually automated so there is no need to have many operators on the job. This leads to a decrease in manufacturing jobs.

Finally an issue that could pose a problem is the possible inaccuracy of the design. There are printers out there that have a tolerance that is lower so your original design might not come out the way you were expecting it to. It can always be fixed in the final part of processing but it is something to consider which will most likely cost you more in production.

In a world grappling with environmental challenges, the need for sustainable and resilient solutions has become paramount. 3D printing, also known as additive manufacturing, holds great promise in addressing these challenges by offering innovative approaches to production. This article delves into the ways in which 3D printing can contribute to sustainability and resilience, ultimately shaping a better future for our planet.

Environmental Impact of Traditional Manufacturing

Traditional manufacturing methods often involve high material consumption, wastage, and energy-intensive processes. Additionally, global supply chains necessitate long-distance transportation of goods, leading to increased carbon emissions. These factors contribute to the environmental footprint of conventional manufacturing practices, making them less sustainable in the long run.

Promoting Sustainability through 3D Printing

Material Efficiency

One of the key advantages is its ability to optimize material usage. Traditional manufacturing often generates significant waste due to subtractive processes, whereas 3D printing only uses the necessary amount of material for creating an object. This reduction in material waste not only saves resources but also reduces the environmental impact.

Waste Reduction

In addition to material efficiency, 3D printing also enables the utilization of recycled or biodegradable materials. By incorporating sustainable materials into the printing process, the environmental impact can be further reduced. Moreover, the ability to create complex structures minimizes the need for assembly, leading to fewer additional parts and less waste generation.

Localized Production

3D printing has the potential to transform global supply chains by enabling localized production. Instead of relying on centralized manufacturing facilities and long-distance transportation, products can be printed on-demand and closer to the end-user. This localized approach reduces transportation emissions and promotes sustainability by minimizing the need for excessive inventory and storage.

Resilience and Adaptability

The ability to rapidly respond to changing circumstances is crucial in times of crisis or disaster. 3D printing offers unparalleled resilience and adaptability by facilitating quick production and customization. Whether it’s manufacturing critical spare parts during emergencies or adapting designs to meet evolving needs, it enhances resilience and ensures the availability of essential items in a timely manner.

Applications of 3D Printing for Sustainability and Resilience

Sustainable Product Design

3D printing allows designers to explore innovative and sustainable approaches to product development. With the flexibility of additive manufacturing, complex geometries can be created that optimize material usage and reduce waste. This opens up new possibilities for lightweight, resource-efficient designs, promoting sustainability across industries such as automotive, aerospace, and consumer goods.

Renewable Energy

The renewable energy sector can greatly benefit from 3D printing technologies. From optimizing the design and production of wind turbine components to manufacturing solar panels with increased efficiency, additive manufacturing techniques contribute to the advancement of sustainable energy solutions. Additionally, 3D printing enables the fabrication of energy storage systems and the development of customized solutions for off-grid communities.

Disaster Response and Relief

During natural disasters or humanitarian crises, access to essential supplies is often limited. 3D printing offers a viable solution by providing the capability to produce emergency items on-site. From temporary shelters and medical equipment to tools and spare parts, it empowers local communities and relief organizations to respond swiftly and effectively in challenging circumstances.

Future Prospects and Challenges

As 3D printing continues to evolve, its potential for sustainability and resilience grows even further. Advancements in materials, printing speed, and scalability are expanding the range of applications and improving the overall efficiency of the technology. However, challenges such as the availability of sustainable materials, regulatory frameworks, and cost-effectiveness need to be addressed for widespread adoption and integration into existing systems.

Conclusion

3D printing represents a paradigm shift in manufacturing that holds immense promise for sustainability and resilience. By reducing material waste, enabling localized production, and fostering adaptability, this technology offers solutions to environmental challenges and enhances our capacity to respond to crises. Embracing 3D printing as a tool for sustainable and resilient development is crucial for creating a more resource-efficient and resilient future.

Frequently Asked Questions (FAQs)

Can it be used for large-scale manufacturing?

Yes, it can be scaled up for large-scale manufacturing. However, factors such as production time, cost, and the availability of suitable materials need to be considered.

Is it environmentally friendly?

Compared to traditional manufacturing, 3D printing has the potential to be more environmentally friendly due to its material efficiency and localized production capabilities. However, the sustainability of 3D printing depends on factors such as material selection and energy consumption during the printing process.

What are the limitations of 3D printing?

Some limitations include the restricted range of available materials, the need for specialized equipment, and the time required for printing complex objects.

Can 3D printing contribute to disaster relief efforts?

Yes, it has shown great potential in disaster relief efforts. It enables the rapid production of essential items and spare parts, facilitating timely response and recovery in affected areas.

How can 3D printing benefit the healthcare industry?

In the healthcare industry, it can be used for personalized prosthetics, medical implants, and the creation of anatomical models for surgical planning. This technology offers greater customization and precision, leading to improved patient outcomes.